Semiconductor Solutions

With 20+ years in capital equipment control, AltaStream delivers semiconductor automation that scales from single tools to complex, multi controller systems. We build robust embedded equipment control, supervisory control with graphical HMI, and remote monitoring & data logging on proven frameworks supporting PLC logic and C/C++/Java controllers. Typical networks include Ethernet TCP/IP, Modbus TCP/IP, Serial (RS-485/232), and CAN. Features such as sequencing, alarming, user-level security, recipe handling, custom reporting, and historical data give fabs clearer diagnostics, safer operation, and faster issue resolution.

Products

AltaStream provides industrial control products designed to assist clients in delivering world class solutions. AltaStream’s industrial control system products comprise all layers of in-fab control. From host simulation at the top, to direct control of devices at the bottom; our pre-integrated, highly configurable control layers are both modular (when you only need a component) and integrated (when you need the entire functional body). Additionally, all products can be extended and customized through a variety of well-defined external interfaces.

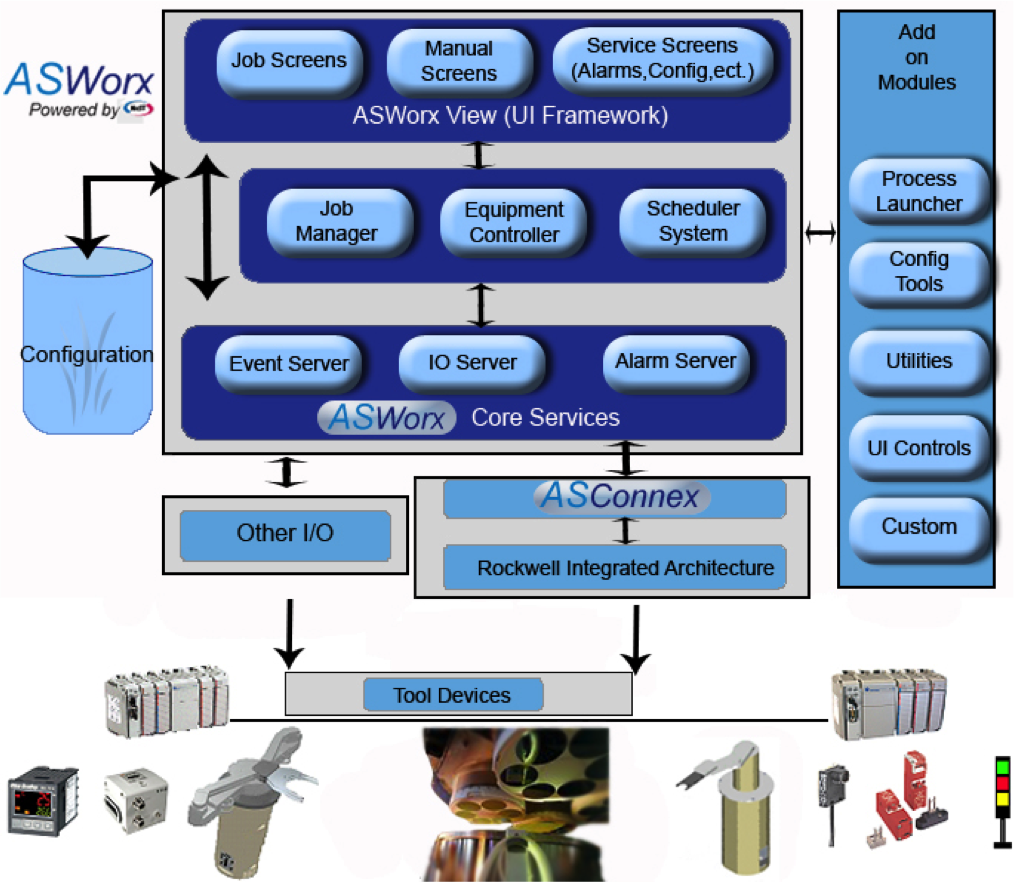

ASWorx

ASWorx is an industry hardened control system framework. This combines highly configurable, predeveloped, preintegrated system control features with application services which enable your product will hit the market sooner, with more features and with higher reliability.

ASWorx is an industry proven approach to equipment automation. By combining highly configurable, predeveloped, preintegrated system control capabilities with application services and field engineering, this approach allows for new products to be introduced to the market sooner, with more features and robustness. With ASWorx, developmental risk is managed, and engineering time is reduced, allowing companies to focus engineering efforts on other critical aspects of product development.

The Semi E95 compliant user interface is comprehensive and designed to meet the levels of control required by multiple user classes.

The ASWorx Software Architecture provides full support for tool scheduling, lot control, material handling, process management, event and alarm management and user interface.

ASWorx combines product and service offerings in a comprehensive and cost-effective way. Services are offered globally and are performed by control system professionals with years of knowledge and experience in capital equipment. AltaStream supports ASWorx clients through the product development phase and continues to offer support through rollout to production and global deployment. The AltaStream team becomes an extension of the client’s organization by tailoring our methodology to the client’s project development process.

Equipment Control

PLC/embedded control with sequencing, alarms, and closed loop logic fit for complex tools with hundreds of I/O or compact, portable systems.

Supervisory Control & HMI

System-level control with graphical visualization, alarms, user security, recipes, and reports built on FactoryTalk View or C++ where appropriate.

Remote Monitoring & Data

Real-time and historical logging, drill down to equipment, and email/SMS notifications; synchronized event/time data stored in MySQL.

Fixed-price, T&M, Architecture & Test

AltaStream offers four engagement models to reduce risk and speed delivery: fixed price system engineering, time and materials engineering, system architecture & design consulting, and software quality & automated test services. We work on site, at end user facilities, or at AltaStream locations, matching the delivery approach to your schedule and compliance needs. Our standard process covers requirements capture, project planning and quoting, proposal sign-off, development offshore, integration onshore, and ongoing support so semiconductor programs move from concept to release with clear checkpoints and predictable milestones.

Backed by 20+ years in capital equipment control (with a focus on semiconductor and related manufacturing), our teams integrate embedded control, equipment /supervisory level control, and remote monitoring & data logging using proven frameworks. We support PLC logic and C/C++/Java controllers over Ethernet TCP/IP, Modbus TCP/IP, Serial (RS-485/232), and CAN. For larger initiatives, our Offshore Development Centers (CMMI Level 5) scale from small focused groups to enterprise level teams, flexing resources from 4 to 400 engineers as project loads change.

Quality is built in: we provide simulated test capabilities under automated test environments, enabling continuous testing with high integrity hardware simulation. Combined with documentation, operator training, and lifecycle support, this approach shortens time to market, improves reliability, and lowers total program risk so your tools reach production with the performance and visibility you expect.