Testbeds & Validation

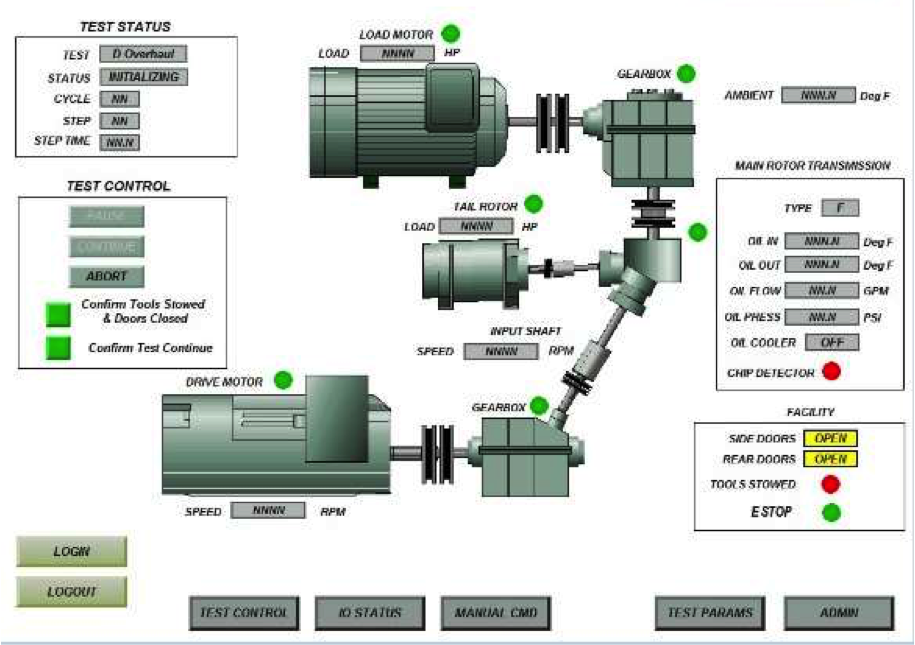

Deploying a new system using regenerative energy can have very significant impact on the total cost of ownership. AltaStream has developed a transmission test bed solution that achieves over 80% energy regeneration. Normally, when testing transmissions, the input shaft requires a specified amount of energy during the duration of the test. (ie 600 HP for 1 hour). To load the output shaft of the transmission, the typical solution has been to use hydraulic clutches that transform the load energy into heat, which is then dissipated utilizing chillers or radiators. AltaStream’s regenerative solution captures the output shaft energy electrically, and then feeds it back to the input drive shaft, with a net energy saving of 83%. Whereas a 600 HP test stand traditionally requires almost 500 kW of energy, we can now achieve the same test capability utilizing only 80 kW of energy.

Our solution provides very precise control of the load torque and allows the customer to configure the specific load profile that they need to test. With full graphical display, alarms and safety features, datalogging, and custom report generation, the control solution meets a wide range of customer requirements. Features include in-situ calibration capability for the torque sender, state-of-the-art networked drives, and industrial reliability of an Allen Bradley PLC.

Rapid Prototyping & HIL

Validate control logic with hardware in the loop simulation and run full sequences safely in the lab.

Automated Test Environments

Continuous, repeatable tests with alarm/sequence checks to prove reliability ahead of deployment.

Data Logging & Diagnostics

Real-time and historical logging with drill down, 1 second records, and email/SMS alerts for early warnings.

Testbeds & Validation

AltaStream builds automation testbeds to derisk delivery and shorten time to market. Our environments combine real controllers (PLC logic or C/C++/Java embedded controllers) with hardware simulation so you can exercise sequencing, alarming, and closed loop control before equipment reaches the field. Testbeds connect over the same industrial networks used in production Ethernet TCP/IP, Modbus TCP/IP, Serial (RS-485/232), and CAN and include graphical visualization so teams can drill down to engines, actuators, and sensors just as they would on live systems. We run automated test environments for continuous testing, capturing real time and historical data with synchronized event and time based records (down to 1-second resolution) stored in MySQL for analysis and reporting. Optional email/text notifications flag parameters moving outside normal ranges, supporting preventive maintenance and faster troubleshooting. By validating control logic, alarms, user level security, recipes, and reports in the lab, AltaStream helps ensure reliable performance at site reducing risk, improving quality, and keeping schedules on track.Our solution provides very precise control of the load torque and allows the customer to configure the specific load profile that they need to test. With full graphical display, alarms and safety features, datalogging, and custom report generation, the control solution meets a wide range of customer requirements. Features include insitu calibration capability for the torque sender, state of the art networked drives, and industrial reliability of an Allen Bradley PLC.