Automation Capabilities

With over 20 years of experience, AltaStream engineers have the knowledge base and capabilities to automate a very broad range of applications. Whether you need embedded equipment control, a SCADA system, or an IOT (Internet of Things) solution, AltaStream is available to provide you with the automation you need.

Embedded Equipment Control

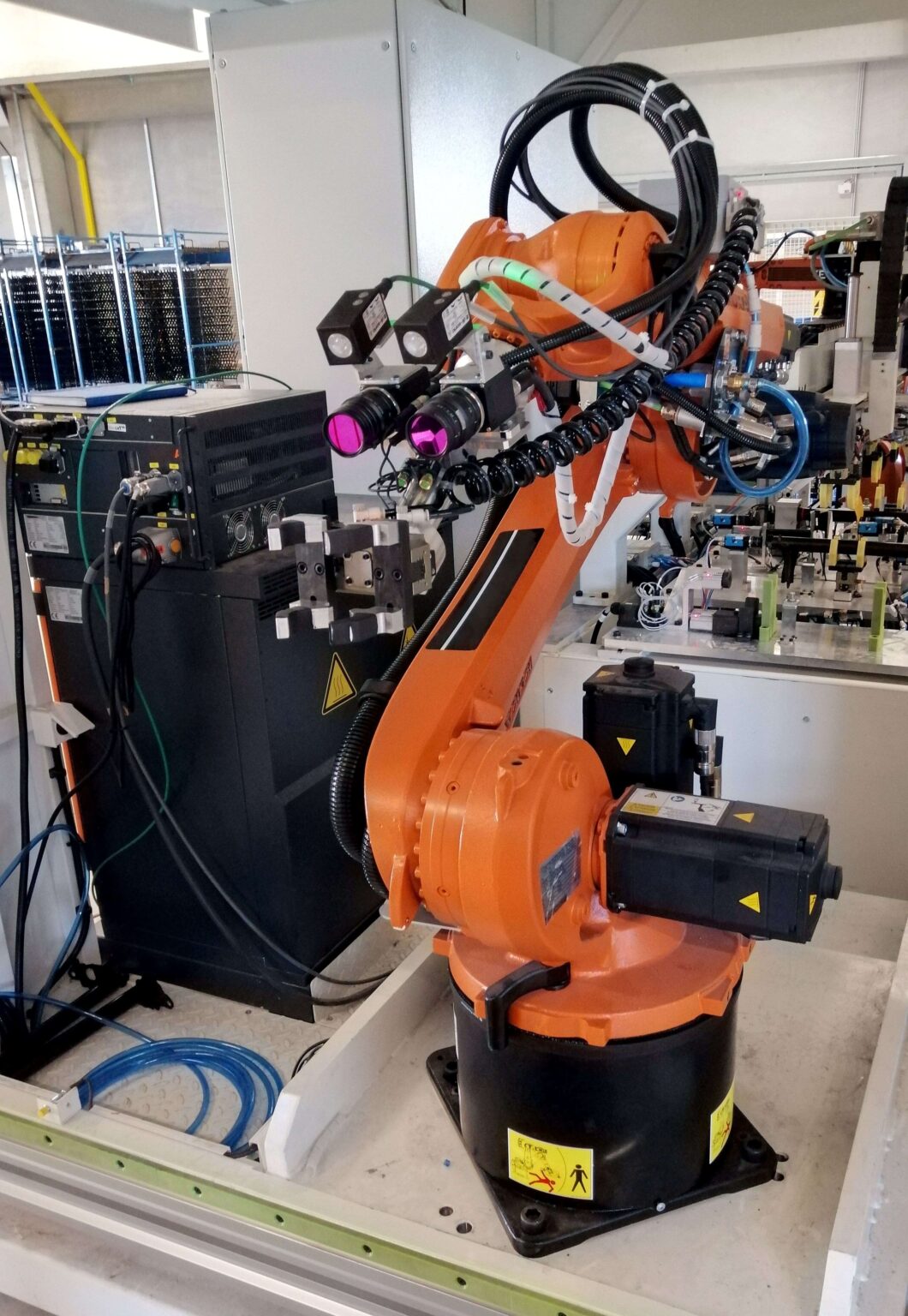

For almost 20 years AltaStream has been developing embedded equipment control solutions. Leveraging a proven framework, and an extensive library of available sensor and control objects, AltaStream builds robust solutions that are full featured with sequencing, alarming and close loop control. Embedded solutions can be programmed for PLC Logic, C, C+, and Java embedded controllers and can range from large complex tools with robotic handling and hundreds of I/O to small Alan Bradley MicroLogix based embedded PLC controls for portable equipment. For situations where customized hardware is required, AltaStream develops multi layer PCB solutions, with or without data acquisition, wiring harnesses, and control panels.

Supervisory Control

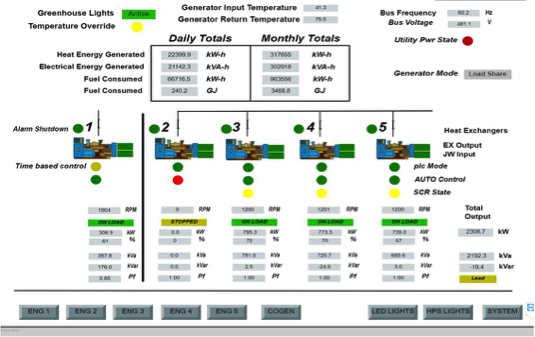

Supervisory or system level control typically requires the monitoring and control of several networked embedded controllers. AltaStream provides these solutions, complete with graphical HMI visualization as part of our full suite of automation capabilities. Data networks typically used include Ethernet TCPIP, Modbus TCPIP, Serial (485 and 232), and CAN. Our supervisory level control solutions are developed using Allan Bradley Factory Talk View or a C++ development environment. Features include visualization graphics (plots, instrumentation, digital readouts), alarm handling, user level security, recipe handling (for batch type jobs), and custom report generation.

Remote Monitoring & Control (IOT)

The ability to remotely monitor and control your equipment provides a critical element in ensuring your operation stays online and profitable. AltaStream’s control architecture enables remote monitoring and control of plant installations, delivering only the capabilities that are required. Features include real time and historical datalogging of all plant parameters, the ability to drill down into the embedded equipment to determine and manage issues, as well warning and alarm notifications via email or text message. AltaStream’s synchronized data, which supports both event and time based data (with 1-second resolution), is stored in industry standard databases such MySQL which allows easy integration of third party tools for visualization and data mining.

Engineering

AltaStream offers services in specialized fields for OEMs and factories. Working as either an integral part of a client’s team or as an independent project team, AltaStream’s expertise will reduce developmental risk and improve time to market in today’s highly competitive global economy.

AltaStream provides four categories of engineering services: fixed price system engineering, time and materials engineering, system architecture and design consulting, and software quality and automated test services. Our engineering services are backed by extensive experience in our target markets and leverage a multilevel delivery model to maximize return on investment (ROI). Services are provided either at the customer’s site, the end users’ site, or at one of AltaStream’s facilities.

Fixed Price System Engineering

AltaStream accelerates the customization, integration, and deployment of control system solutions based on our expert engineering services. Over the last 20 years, our engineering team has developed and supported control system applications for dozens of capital equipment projects. We specialize in control systems for electromechanical capital equipment, with focus on semiconductor and similar device fabrication. Our fixed price engineering process includes a requirement gathering phase, project planning and quoting, proposal sign-off, development offshore, integration onshore, and ongoing support. The software is delivered based on a fixed price and schedule. Our delivery phase is executed on a global basis, wherever the target equipment happens to be.

Time and Materials Engineering

In many circumstances, our customers elect to manage our expert resources directly. This is beneficial in situations that require responsiveness to end-customer needs and when tackling a variety of small to medium sized efforts. Our engineers can function directly under management by your engineering managers. This provides the flexibility and responsiveness that is critical in key phases of product development and deployment.

Fast Time to Market

+

High Tech Solutions at Reduced Cost

+

Total Solutions Under One Roof

=

Successful Product Release

Offshore Development Centers at CMMI Level 5

A key strategy for reducing the cost of software development in general is employing Offshore Development Centers. AltaStream offers offshore development center resources for teams from 4 to 400. These teams operate under the direction of their assigned customer and at a high-level of capability and autonomy. The resource levels are highly flexible and rise and fall as projects runs their courses and business cycles ensue.

System Architecture and Design Consulting

For projects that are still fresh on the drawing board, AltaStream brings decades of experience to the task of analyzing system-level architecture and design concerns. There are a range of typical concerns regarding the execution environment such as; being centralized or distributed, involving data collection and transmission levels, operating system selection, defining network environments, user-classes and user needs, and interfacing to the factory, the human user, and the controlled components and subsystems. Defining the architecture appropriate to the expected system features and behavior is critical to the success of product development. AltaStream’s performance in this area is unmatched.

Software Quality and Automated Test Services

For capital equipment control systems, delivering and maintaining quality presents unique challenges. System design changes frequently during product development, but the schedule typically does not accommodate these changes. In the face of this reality, AltaStream provides simulated test capabilities under automated test environments. These automated test services test code continuously, with high integrity simulation of the hardware.

Embedded Equipment Control

Robust PLC/embedded control with sequencing, alarming, and closed loop logic scales from complex tools to portable equipment (incl. MicroLogix).

Supervisory Control & HMI

System level control with graphical visualization, alarms, security, recipes, and reports using Allen-Bradley FactoryTalk View or C++ where appropriate.

Remote Monitoring & Control

Real time and historical data logging, drill down to equipment, and email/SMS notifications; synchronized event/time based data stored in MySQL.